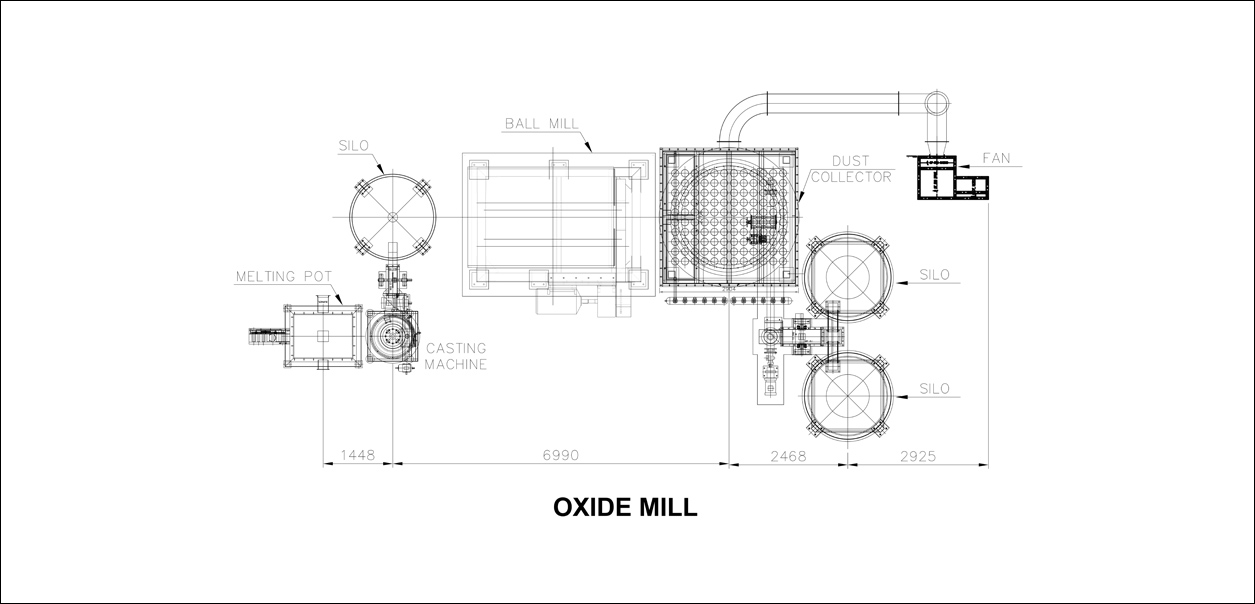

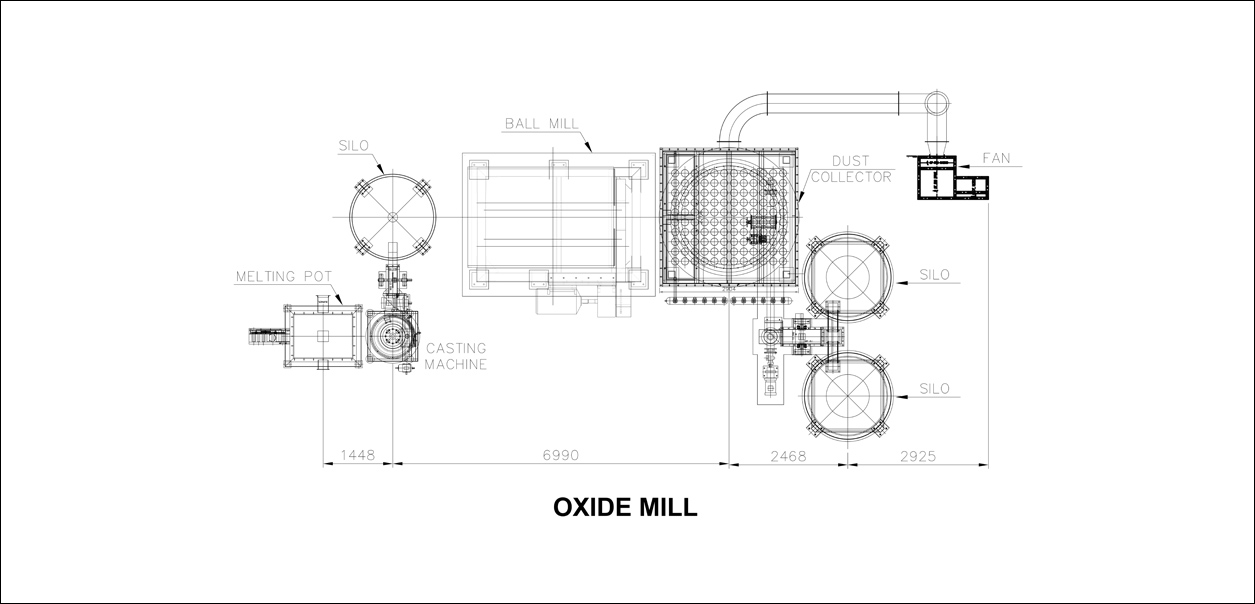

Ball Mill Type Oxide Manufacturing Systems

Lead Ingots are melted in the Melting Pot. The Molten Lead in the Melting Pot is pumped on to the

Cylinder casting Machine. The Lead cylinders are casted in the Cylinder casting machines at a rate higher

than that of the oxidation process. These Lead cylinders are conveyed and stored in a Silo.

The Silo feeds the required amount of Lead Cylinders into the Mill as and when required. The amount of

Lead Cylinders being discharged from the Silo is adjustable from the PLC system. Lead Cylinders tumbling

inside the Ball Mill drum create heat due to friction between them. This heat initiates the oxidation

process. The oxidation process is also an exothermic reaction. This exothermic heat raises the

temperature of the material which in turn accelerates the oxidation process. A draft of air through

the Ball Mill drum gives oxygen for the oxidation process and also carries the Battery Oxide to the

collection system.

The Collection System includes a combination of cyclone and dust collector or just dust collector.

Battery oxide is collected and conveyed to storage silos. The Silos storing Battery Oxide are purged with

Nitrogen to keep the temperature of the Oxide in check.

Process control

- Reaction temperature

Reaction temperature is monitored using thermocouples and is controlled by periodic water cooling.

- Load in the Ball Mill

The Load in the Ball Mill can be monitored by Load cells or by current consumption. According to the load in

the mill, new material is fed automatically when the load reduces.

- System draft

The System draft or air flow through the ball Mill is very precisely controlled and monitored. The air flow

volume is controlled by a motorized butterfly valve and te correspondin static pressure is monitored by

pressure sensors.

Other features

- Fully Automatic with PLC based Control system

- Totally Enclosed System

- Touch Screen Based Interface

- One Button Start / Stop

- 24 Hour Operation

Litharge specification :

| Oxide Specifications |

Unit |

Range |

| Total PbO |

% |

75 - 68 |

| Free Lead |

% |

25 - 32 |

| Apparent density |

Grams / cc |

1.2 - 1.6 |

| Acid Absorption |

Mg / gram |

220 - 260 |

| Average Particle |

Micron |

2 - 3 |

Production Rate:

| Model |

Capacity |

| ACS / BLM / 6T |

6000 Kg / 24Hrs |

| ACS / BLM / 8T |

8000 Kg / 24Hrs |

| ACS / BLM / 12T |

12000 Kg / 24Hrs |

ACS Lead Tech

ACS Lead Tech

![]()